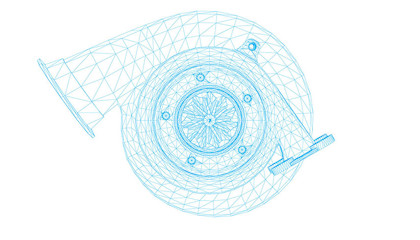

The turbocharger – more outputs from small engines

Sandvik’s face milling cutter is developed exclusively for machining of turbo exhaust housings in turbochargers.

The turbocharger is essentially a gas-driven turbine, rotating at more than 300,000 rpm. By compressing a large volume of ambient air for combustion, it makes a vehicle’s engine run cleaner and more efficiently.

The exhaust side housing in a turbocharger must be able to operate in temperatures ranging from 850 to more than 1,300 degrees Celsius (1,560 to 2,370 degrees Fahrenheit). The heat-resistant materials and other technologies, such as aerodynamics, rotor dynamics and testing procedures, are not unlike those used in the aerospace industry.

Turbocharging is a key enabler for increased vehicle power density or, in other words, getting more output from smaller engines. As demand for smaller, more efficient engines increases, some 85 percent of all new light vehicles in Europe are likely to be turbocharged by 2020.