Powered by pressure

Sandvik has offered solutions for the automotive industry since the 1940s. The customer challenges have evolved since then, but the development has never been faster than what it is today, when environmental concern drives the progress relentlessly.

The European Union recently agreed to enforce stricter rules on carbon dioxide emissions for EU cars and the regulations in China are constantly getting tougher. The Obama CAFE standards (Corporate Average Fuel Economy) now really begin to require new thinking for automakers for cars and trucks sold in the United States, beginning in 2015. Accordingly, the automakers struggle to limit the car weights to meet the stricter standards.

Drivers for innovation

Customer challenges are often the key that opens a new door. A few years ago, a Sandvik engineer met with a customer who needed light and strong tubes for a new gasoline direct fuel system (GDI) design. It had to be strong enough to master substantially higher pressures than the conventional material solutions. We met with global product manager Jari Ponsiluoma at Sandvik Materials Technology to discuss how Sandvik meet these new demands.

"Our answer to the automotive industries challenges in this area is Pressurfect™," says Ponsiluoma.

"Our answer to the automotive industries challenges in this area is Pressurfect™," says Ponsiluoma.

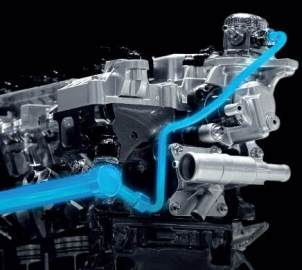

He continues by saying that by reducing the number of cylinders, including new engine technology such as Gasoline Direct Injection (GDI) you will get a lighter engine with less emission and reduced fuel consumption. With today's gasoline direct injection (GDI) engines you get the same performance with a V6 engine as with the former V8 engine. It is all about down-sizing the engine with maintained performance. This requires substantially higher pressure, which means that the tube material needs to have higher fatigue strength to withstand new fuel blends and internal and external corrosion due to the tough environment. That was our starting point.

What is Pressurfect?

Pressurfect is developed for both fuel rail and fuel line applications and are strong stainless seamless tubes that can master pressures for today's engine designs.

The standard Pressurfect tubes are made of austenitic chromium-nickel steel with low carbon content.

For even higher demands, we have developed Pressurfect XP™ – an up to 40% lighter, even more advanced duplex stainless steel tube with higher mechanical strength and with superior corrosion resistance. Due to the high pressure, there is no room for mistakes.

Future outlook for the automotive industry?

By 2020, around 30 million cars will be produced in China alone, 107 million worldwide. With the new regulations in place, that's a lot of cars with GDI-motors. Each motor program lasts for five to six years, so the potential is huge.

The pressures will be even higher in future car models. I would say that large cars won't consume more than around 0.4-0.5 litres of gasoline per mile before long. Right now, there are no other tubes on the market that can match Pressurfect, so I am really optimistic.

When will there be a Pressurfect tube in my car?

You might already have it! Our solution is used in close to half a million GDI engines, including the Ford EcoBoost-engine.