Boosting innovation

Innovation is strong at Sandvik. In 2012, 200 researchers from all five business areas met and were challenged to imagine innovations that would drive the company's growth.

Imagine that it is 2020, and your task is to award a prize for the best Sandvik innovation. What kind of invention would it be? That question, presented at a Sandvik R&D conference in Stockholm, triggered a burst of creativity among more than 200 researchers from the group's five business areas. The exercise provided a perfect image of a successful research collaboration.

R&D reorganization

In the past, Sandvik's R&D was handled separately by the different business areas, but it has been reorganized. For the first time, R&D has a head of global research in the Executive Management Group, professor Olle Wijk. He also heads the R&D Board with representatives from the five business areas as well as being Head of R&D at Sandvik Materials Technology.

"Increased collaboration across the Group will take our innovation to even higher levels," says Olle Wijk. It is an ambitious goal for a company that thrives on innovation. Sandvik invests SEK 3 billion per year in R&D and has about 6,000 patents. In 2013, the American business magazine Forbes named Sandvik the 73th most innovative company in the world.

"Innovation is a key to success, and we are very innovative," Olle Wijk says. "The focus now is to increase the pace and producemore products in a shorter time", he continues.

New sales ratio - the higher, the better

Today, depending on business area, between 20 to 45 percent of Sandvik's invoicing comes from products that were launched in the past five years. "The higher the new sales ratio is, the better for us and our customers," Olle Wijk says. "It shows that we are providing new products that help our customers in their business."

So how can Sandvik get more out of innovation?

The strategy is closely linked to the move towards a more united group. Sandvik has more than 60 R&D centers all of which are typically focused on their own assignments. Contacts between the centers are an obvious improvement area. Olle Wijk and his team are mapping out which experts could be part of cross-business-area networks and which areas have potential for synergies.

Sharing knowledge is crucial

One is simulation and modelling. Sandvik is continuously testing new solutions and constructions in simulations and has gained a high level of expertise in the field. However, much of the know-how is restricted to isolated islands of experts. If the knowledge was shared, it would benefit the whole company and could be developed as a service to customers.

"We are now bringing together experts from various locations, since a closer interaction will clearly improve both speed and quality," says Anna Hultin Stigenberg, a principal project manager who was assigned by the R&D Board to get the project on track.

Other promising areas of broad co-operation include:

- Material characterization, which involves advanced investigations of materials

- Powder metallurgy, which deals with blending, forming and sintering of fine powdered materials

- Joining technology, such as different types of welding

- Product sustainability

- Non-destructive testing.

Time for innovative thinking

The R&D Board is also on the look-out for ground-breaking inventions. It is very important to have an environment where there is time for "free thinking" parallel to the structured processes for innovative work. This has led to the development of a wide range of inventions outside core activities.

One example is Sanicro 25, an alloy developed by Sandvik, can handle temperatures of up to 700 degrees Celsius and pressures up to 350 atm. It has been approved by the EU for use in tubing in coal-fired power plants. It allows for higher burning temperatures and pressures, which can radically reduce carbon dioxide emissions.

Another side-project invention is the telescopic chute WE8000i that consists of a series of cone segments. It is asimple construction, but it effectively minimizes dust emissions when stockpiling powder material.

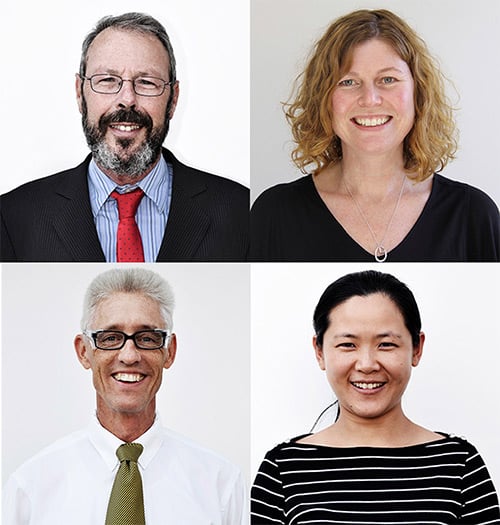

Dynamic quartet awarded for innovation. Clockwise: Gerold Weinl, Sandvik Machining Solutions, Malin Mårtensson, Sandvik Mining, and Torbjörn Selinder and Rachel Shao of Sandvik Venture were awarded the Sandvik Innovation Prize 2012 for a new technology platform that provides metal cutting tools based on PcD (polycrystallinediamond) and PcBN (polycrystalline cubic boron nitride).

Dynamic quartet awarded for innovation. Clockwise: Gerold Weinl, Sandvik Machining Solutions, Malin Mårtensson, Sandvik Mining, and Torbjörn Selinder and Rachel Shao of Sandvik Venture were awarded the Sandvik Innovation Prize 2012 for a new technology platform that provides metal cutting tools based on PcD (polycrystallinediamond) and PcBN (polycrystalline cubic boron nitride).

Advanced cutting tool materials are a key growth area for Sandvik."We are providing new products that help our customers in their business. Boosting innovation is about creating the best possible environment for innovators," Olle Wijk says.

The new organization represents a new phase, with more collaboration, more expert networks between business areas and more effort directed towards finding synergies. Researchers welcome the move, as was evident at the conference in Stockholm. Anything that triggers more innovation, like a challenging exercise, raises their level of creativity.