Sandvik launch 3D printing of components in super-duplex stainless steel

Sandvik and part subsidiary BEAMIT Group announce a unique capability to additively manufacture components in super-duplex stainless steel, an alloy combining mechanical strength with very high corrosion resistance.

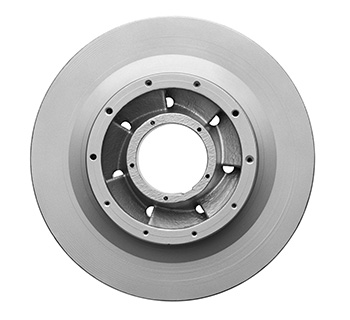

3D printing now allows for on-demand production of spare parts in super-duplex stainless steel. This impeller is one example.The components printed in Osprey® 2507 metal powder show superior properties compared to components manufactured by conventional methods like forging and casting. This makes them particularly suitable to withstand harsh offshore environments.

3D printing now allows for on-demand production of spare parts in super-duplex stainless steel. This impeller is one example.The components printed in Osprey® 2507 metal powder show superior properties compared to components manufactured by conventional methods like forging and casting. This makes them particularly suitable to withstand harsh offshore environments.

Sandvik has already presented a 3D-printed “impeller reinvented” – a lighter, faster, and more efficiently manufactured offshore essential, developed in collaboration with energy giant Equinor and Norwegian Eureka Pumps. Now projects across various marine segments, where super-duplex stainless steel often is the material of choice, are ongoing.